| WIL Specifications | ||

| Construction | Wilton Weave | |

| Yarn Composition | 100% Solution Dyed Heatset Polypropylene | |

| Tufted Pile Weight | Ca. 1510 g/m² (45.5 oz/yd²) | |

| Total Weight | Ca. 2150 g/m² (63 oz/yd²) +/- 5% | |

| Pile Height | Ca. 7 mm | |

| Standard Roll Size | 4 m x 30 m | |

| (as tested by ITTS Inc. USA) | ||

| Stain Resistance | 10 (AATCC-175-2003) | |

| Static Control | Pass – Max. 4 kV (AATCC 134-1996) | |

| Tuft Bind | Pass – 4.3 lbs (ASTM-D-1335) | |

| Dimensional Stability | Pass – Max. 0.2% change (AACHEN) | |

| Flammability | ||

| – Pill Test | Pass – 8 (ASTM-D-2859-06) | |

| – Smoke Density | Pass – Max. 450 (ASTM-E-662-06) | |

| – Hot Metal Nut |

Pass – Low Radius Of Effects Of Ignition (BS4790)

|

|

| Colourfastness | ||

| – to light | Excellent – 5 (AATCC-16E) | |

| – to wet & dry crocking | Wet – 4, Dry – 3 (AATCC-165) | |

| – to ozone | Excellent – 5 (AATCC-129) | |

| Lifetime Antishock Carpet Warranty | ||

| Ideal for Medium Commercial and Hospitality Use. | ||

| The subfloor should be dry, smooth, flat, dust-free and resistant to compression and load-bearing. Where seaming is necessary, a seam sealant must be used for all such installations. Due to dye lot variations, actual color may vary slightly from the samples. Chair pads are recommended to prevent premature wear of carpet. | ||

| Suitability | ||

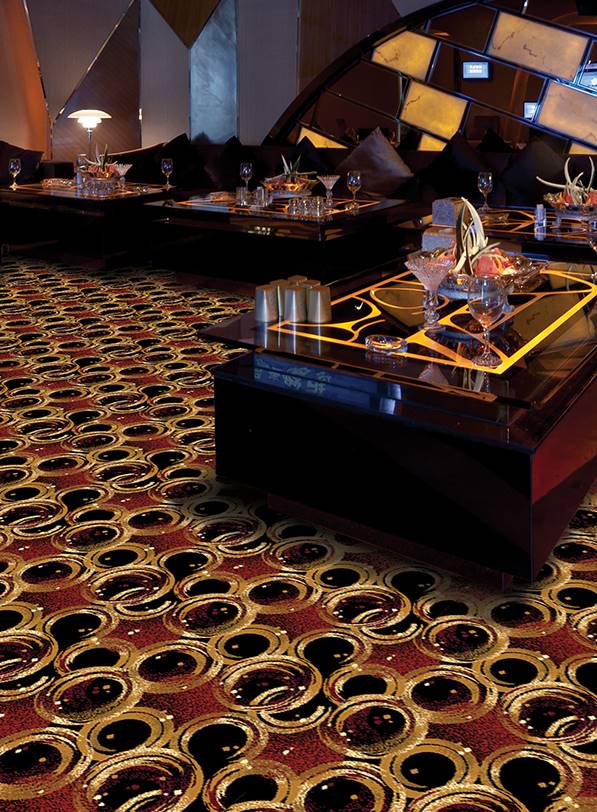

| For Public Areas, Corridors, Guest Room, Restaurant, Casino, VIP Lounge, Staircase, etc. | ||