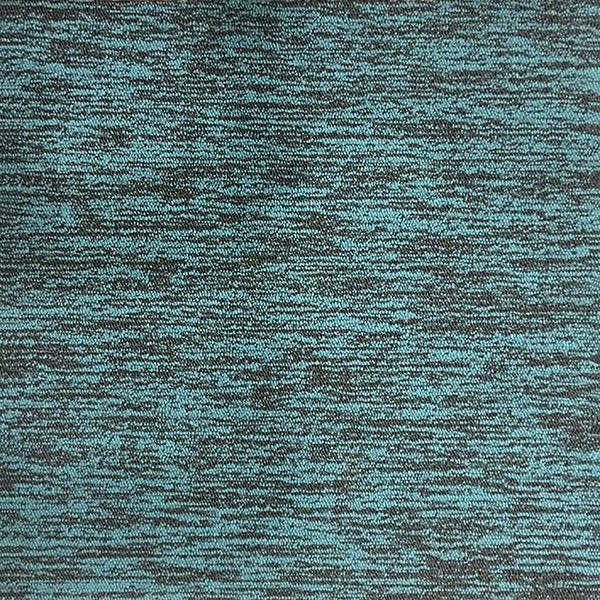

| TRF-1 Specifications | ||

| Construction | 1/10” Level Loop Pile | |

| Yarn Composition | 100% Solution Dyed Nylon | |

| Tufted Pile Weight | ca. 576 g/m² (17 oz/yd²) (+/- 10%) | |

| Total Weight | ca. 2500 g/m² (74 oz/yd²) | |

| Pile Height | ca. 3 mm (+/- 0.5 mm) | |

| Total Height | ca. 5 mm (+/- 0.5 mm) | |

| Backing | EcoAir – “PVC Free” | |

| Size | 50 cm x 50 cm | |

| Packing | 30 pcs per box (7.5 m²) | |

| Performance | (as tested by ITTS Inc. USA) | |

| Static Control | Pass – Max. 4 kV (AATCC-134-1996) | |

| Tuft Bind | Pass – 11.4 lbs (ASTM-D-1335) | |

| Dimensional Stability | Pass – Max. 2.4% change (AACHEN) | |

| Indoor Air Quality (V.O.C.) | Pass – No VOC Detected (ASTM-D5116-10) | |

| Impact Sound Insulation | ΔLᴡ: 28 dB (ISO 10140) | |

| Sound Absorption | αᴡ = 0,25 (H) (ISO 354) | |

| Hz 125 250 500 1000 2000 4000 | ||

| αs 0.00 0.05 0.30 0.20 0.20 0.25 | ||

| Flammability | ||

| – Radiant Panel | Pass – Class I (ASTM-E-648-10) | |

| – Pill Test | Pass – 8 (ASTM-D-2859-96) | |

| – Smoke Density | Pass – Max. 450 (ASTM-E-662-06) | |

| Colourfastness | ||

| – to light | Excellent – 5 (AATCC-16E) | |

| – to wet & dry crocking | Excellent – 5 (AATCC-165) | |

| – to ozone | Excellent – 5 (AATCC-129) | |

| Lifetime Anti-shock Carpet Warranty | ||

| Ideal for Heavy Contract Use. | ||

| The subfloor should be dry, smooth, flat, dust-free and resistant to compression and load-bearing. The seams may remain visible to the eye and this should be accepted as an inherent characteristic of carpet tiles. Due to dye lot variations, actual colour may vary slightly from the samples. Chair pads are recommended to prevent premature wear of carpet. | ||

| Environment | ||

| The design and production of TRF-1 Tile conforms to the ISO 14001:2004 Environmental Management System and complies with environmental regulations.

As a responsible manufacturer and to minimize our carbon footprint, a majority of our excess production materials are recycled in-house resulting in a minimum of 10% recycled content in our tile backing. TRF-1 Tile does not contain any PVC in its manufactured materials and packaging. TRF-1 Tile is an environmentally friendly “green” carpet. |

||

|