Electrical mats for insulation, also known as switchboard room mats, are crucial for safety in low, medium, and high voltage areas, providing essential protection against dangerous electric shock. These rubber mats can cover entire floors or specific work areas and are available in various voltage grades (LV, MV, HV). Please refer to the chart below for voltage specifications.

- Electrical Insulation Mats, Switchboard Room Rubber Mats, and electrical Safety Mats meet the standards of either IEC 61111:2009 or ASTM D178-01.

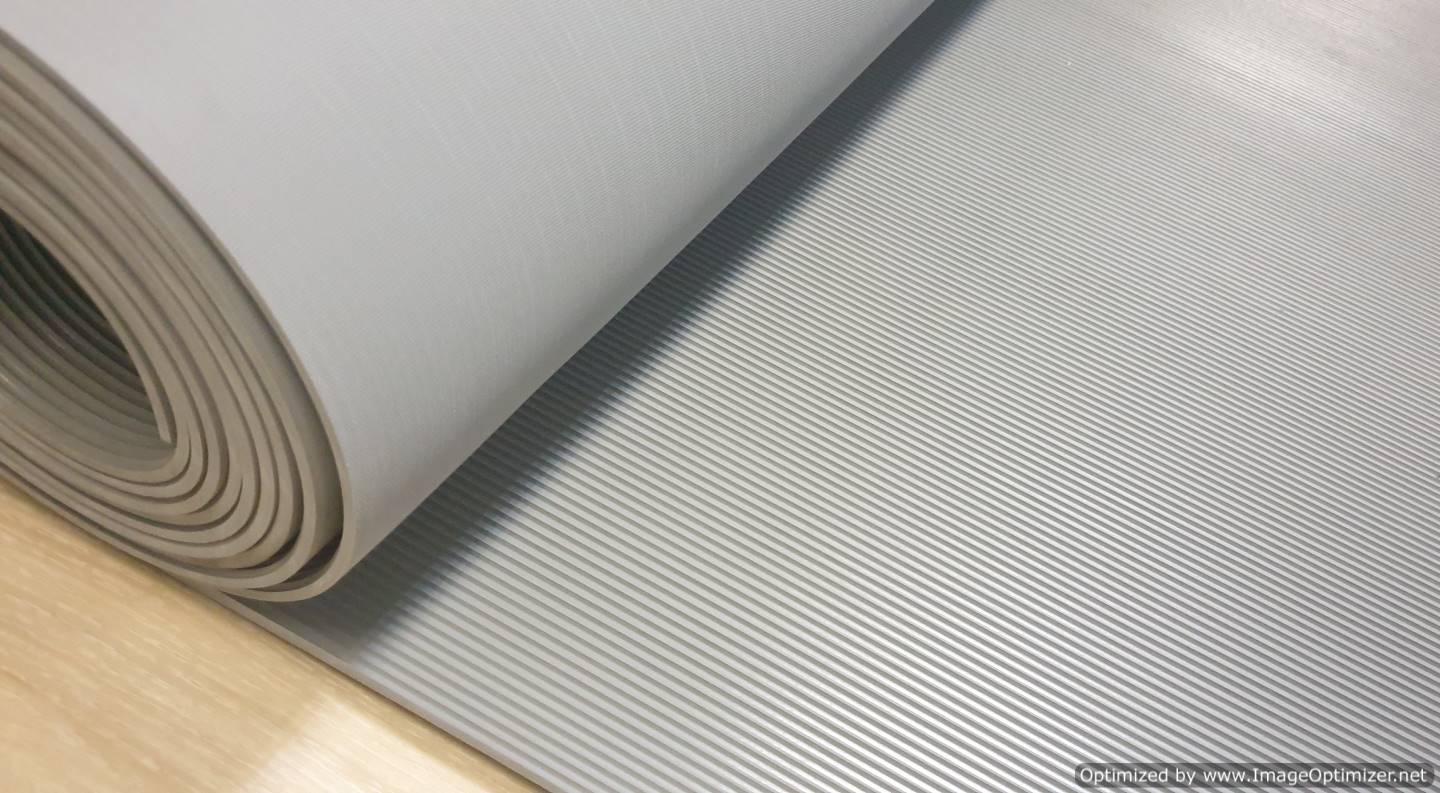

- Electrical Switchboard Matting is used as a floor covering in areas of high-voltage applications for the safety of users from dangerous electrical shock.

- Electrical Safety Mats are flame-retardant.

- Most of these electrical mats come with anti-slip surfaces.

Choosing the Right Class:

It’s crucial to select the appropriate class of electrical insulation mat based on the maximum working voltage of the equipment or area where it will be used. Always choose a mat with a maximum working voltage rating that exceeds the highest voltage you might encounter.

Failing to do so can lead to severe consequences, including:

- Electric Shock: If the mat’s insulation is insufficient for the voltage, it can break down, allowing dangerous current to pass through to anyone in contact with it.

- Arc Flash: Inadequate insulation can contribute to arc flash incidents, which release tremendous amounts of energy, causing severe burns, blindness, and even death.

- Equipment Damage: Electrical faults caused by insufficient insulation can damage valuable equipment.

- Legal and Regulatory Non-Compliance: Using incorrectly rated safety equipment can lead to fines, penalties, and even criminal charges, as it violates occupational safety standards.

Electrical Mat Data with Class

| Model | Thickness (mm) | Roll Size (m) | Class | Test Method | Dielectric Test Voltage | Nominal Maximum Use Voltage |

| Diamond Black | 5 mm | 1 x 10 | Class 0 | IEC 6111:2009 | 10 KV | 1 kV |

| Corrugated Grey | 3 mm | 1 x 10 | Class 2 | IEC 6111:2009 | 30 KV | 17 KV |

| Corrugated Grey | 4.5 mm | 1 x 10 | Class 4 | IEC 6111:2009 | 50 KV | 36 KV |

| Corrugated Black | 9 mm | 1 x 6 | Class 1 | IEC 6111:2009 | 20 KV | 7.5 KV |

| Corrugated Grey | 8 mm | 1 x 6 | Class 2 | IEC 6111:2009 | 30 KV | 17 KV |

| Plain Grey | 12 mm | 1 x 6 | Class 4 | IEC 6111:2009 | 50 KV | 36 KV |

No Class Models

| Model (No Class) | Thickness (mm) | Size (m) | Test Method | Breakdown Voltage |

| Corrugated Black | 3 mm | 1 x 10 | ASTM D178-01 | 17 KV |

| Corrugated Black | 4 mm | 1 x 10 | ASTM D178-01 | 24 KV |

| Corrugated Black | 6 mm | 1 x 5 | ASTM D178-01 | 29 KV |

| Corrugated Black | 10 mm | 1 x 5 | ASTM D178-01 | 43 KV |

Practical Application of Your Advice:

When choosing a mat, consider the following:

- Identify the Maximum System Voltage: Determine the highest possible voltage present in the area where the mat will be deployed. This might be the nominal line voltage, but always consider potential transient overvoltages or fault conditions.

- Refer to the Mat’s Voltage Class: Check the specifications of the electrical insulation mat, whether it adheres to IEC 61111 or ASTM D178. Note its “Maximum Use Voltage” or “Maximum Working Voltage” rating.

- Ensure a Safety Margin: The chosen mat’s maximum use voltage must be greater than the maximum system voltage. It’s often recommended to select a mat class that provides a comfortable safety margin, rather than just meeting the exact voltage. For example, if you are working with 480V equipment, a Class 0 mat (1,000V maximum use voltage) would be appropriate.

- Consider Environmental Factors (for ASTM D178 Type II mats): If the environment has specific challenges like ozone, oil, or a fire risk, opt for ASTM D178 Type II mats with the relevant properties (IIA for ozone, IIC for oil, IIB for flame resistance).

Key points about IEC 61111:

To ensure continuous safety, the electrical insulation mat’s maximum working voltage specifies its safe operating limit. The proof test voltage is used during production to guarantee the mat’s reliability. The withstand voltage demonstrates its short-term ability to handle higher voltages without failing. Colour-coding provides an immediate visual cue to the mat’s voltage class, and IEC 61111 further mandates material properties (like resistance to chemicals and fire), dimensions, and necessary markings.

Key points about ASTM D178:

Like IEC standards, ASTM D178 specifies the maximum use voltage and the proof test voltage for insulating mats. Additionally, ASTM D178 distinguishes between Type I and Type II mats, with Type II offering extra resistance to ozone, flame, and oil. The required thickness of the electrical mat depends on its voltage class, and proper markings and labelling are crucial for verifying standard compliance

Other Product Names:

- Electrical Switchboard Matting

- Diamond Plate Switchboard Mats

- Corrugated Switchboard Mats

- Electrical Safety Matting

- High Voltage Insulation Rubber Mat

- Insulation Mat

- Switchgear Mat

- Electrical Mat

For small sizes, please buy from our Shopee link given below.

Click to buy from our Shopee page