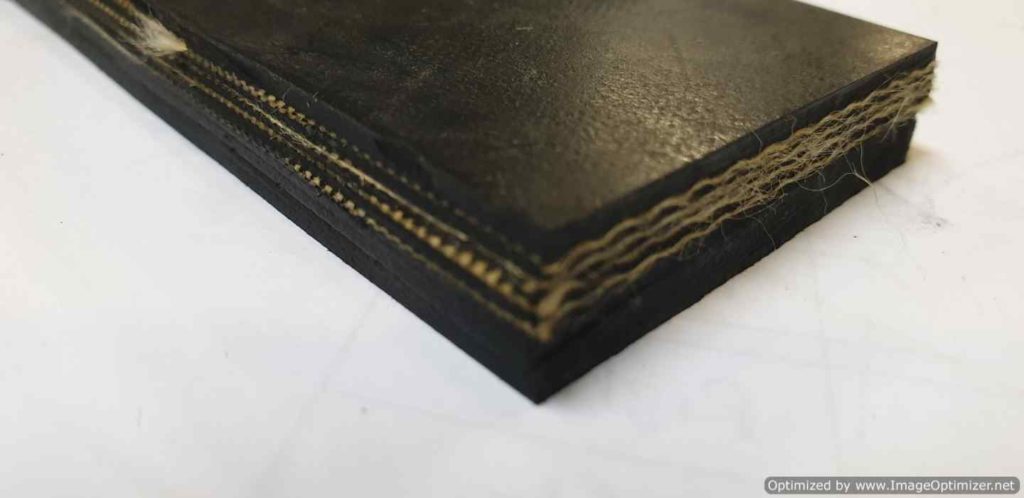

Conveyor Belts are robust and durable rubber plied or solid woven belts. It comes with abrasion and impact resistant, plied with rubber covers. The carcass is made up of 4 plies; each is separated by a rubber layer. The upper and lower fabrics of the belt are then covered with a final rubber cover.

Conveyor Belt Technical Data Sheet:

| DIMENSIONS | Testing Standards | Results | Tolerance |

| Operating temperature | -20 to 80°C | ||

| Belt Thickness | ISO 583 | 10 mm | Up to 10mm: ±1mm and according to ISO14890 |

| Top cover thickness | ISO 583 | 5 mm | -0.3mm |

| Bottom cover thickness | ISO 583 | 1.5 mm | -0.2mm |

| Width | ISO 251 | 1000 mm | +/- 1% |

| Belt weight (indicative) | 13,3 Kg/ml | ||

| CONSTRUCTION MECHANICAL PROPERTIES |

Testing Standards | Results | Tolerance |

| Carcass type | Plied | ||

| Warp yarns | Polyester | ||

| Number of plies | 4 | ||

| Tensile strength warp | ISO 283 | > 500 N/mm | |

| Elongation at break warp | ISO 283 | > 10% | |

| Elongation under 10% load | ISO 283 | < 1,5% | |

| Adhesion between cover and carcass | ISO 252 | > 4 N/mm | |

| Adhesion between plies and plies | ISO 252 | > 4,5 N/mm | |

| COVER MECHANICAL PROPERTIES | Testing Standards | Results | Tolerance |

| Tensile strength at break | ISO 37 | > 14 Mpa | |

| Elongation at break | ISO 37 | > 400 % | |

| Abrasion | ISO 4649 | < 150 mm3 | |

| Hardness | ISO 868 | 62 | +/- 5 Shore A |